In today’s highly competitive and technology-driven manufacturing landscape, precision and productivity are non-negotiable. For companies in the electrical and electronics industries, coil winding is a foundational process that directly affects product quality, efficiency, and cost. Choosing the right coil winder is a strategic decision that can significantly impact your operational success.

Whether you’re producing miniature inductors or complex motor windings, the machine you choose must align with your production requirements, quality standards, and automation goals.

Understanding Coil Winding: The Basics

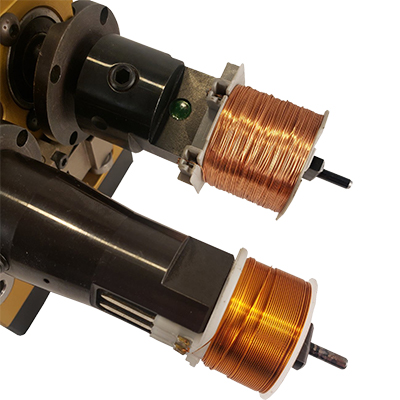

Coil winding involves winding wire around a core to create electromagnetic coils. These coils are critical components in transformers, motors, generators, inductors, and various sensors. Precision in this process ensures uniformity, electrical consistency, and mechanical stability.

There are several types of coil winders, including:

- Manual Coil Winders

- Semi-Automatic Coil Winders

- Fully Automated Coil Winders

- Multi-Spindle Winders

Each type serves different purposes and scales of production. A manual winder might be sufficient for prototyping or low-volume custom jobs, whereas automated multi-spindle winders are designed for high-throughput, high-precision industrial environments.

Key Considerations When Choosing a Coil Winder

1. Production Volume and Throughput Requirements

One of the first questions to ask is how many coils you need to produce within a given timeframe.

- For low-volume and high-mix production, flexibility is paramount. A modular, easily adjustable machine is beneficial.

- Throughput becomes critical for high-volume manufacturing. A multi-spindle coil winder with parallel processing capabilities can dramatically increase output without sacrificing precision.

2. Coil Design Complexity

The geometry and design of your coils – including wire gauge, number of turns, pitch, layering, and terminations – will influence the type of winder required.

- Complex windings demand sophisticated control systems and real-time feedback loops.

- If your products involve integrated processes such as taping, soldering, or testing, your winder must support seamless integration with these steps.

3. Automation Level and Labor Costs

Automation is no longer a luxury but a necessity in competitive markets.

- Fully automated winders reduce operator dependency, minimize errors, and provide consistent quality.

- Automation also allows for lights-out manufacturing, where machines operate unattended during off-hours, significantly enhancing productivity.

At Itasca Automation Systems, our machines are designed with modular automation in mind, allowing businesses to scale up as needed.

4. Precision and Repeatability

In applications such as aerospace, automotive, or medical devices, the margin for error is zero.

- Tolerances of even a fraction of a millimeter can affect performance.

- A high-precision coil winder should offer real-time monitoring and feedback, advanced tension control, and programmable parameters for winding patterns.

Itasca uses modern 3D CAD tools and concurrent design methodologies to ensure exacting tolerances are maintained throughout the winding process.

5. Integration with Finishing Processes

Coil winding is rarely a standalone task. Associated operations such as:

- Terminal insertion

- Soldering

- Taping

- Testing and inspection

…are all crucial in delivering a ready-to-use product. Choosing a coil winder that integrates or interfaces smoothly with these operations saves time, reduces handling, and ensures process continuity.

6. Customization and Flexibility

No two coil winding operations are exactly alike. This is where customization becomes vital.

- Off-the-shelf solutions often fall short of meeting specific production needs.

- A collaborative approach with your machine supplier ensures that the winder is tailored to your product specifications, space constraints, and workflow.

Itasca Automation Systems excels in collaborative, concurrent engineering, providing custom-built machines that align precisely with customer needs.

7. Ease of Use and Maintenance

Advanced features are valuable only when they are accessible and user-friendly. Look for:

- Intuitive Human Machine Interfaces (HMIs)

- Quick-change tooling

- Easy access for maintenance

- Modular components for rapid upgrades or repairs

8. Data Collection and Industry 4.0 Readiness

Smart manufacturing and Industry 4.0 are reshaping the factory floor. The right coil winder should be compatible with modern data systems:

- Real-time production monitoring

- Quality tracking

- Predictive maintenance alerts

- Integration with ERP or MES systems

These features drive smarter decisions and optimize the overall manufacturing ecosystem.

Why Partner with Itasca Automation Systems?

Engineering Excellence

Located on the scenic Door County Peninsula in Wisconsin – a region renowned for its shipbuilding craftsmanship and cherry production – Itasca Automation Systems brings a blend of tradition and innovation to the coil winding industry.

Our team of engineers utilizes state-of-the-art 3D CAD tools and a lean, modular design philosophy to craft machines that excel in both precision and adaptability.

Holistic Automation Solutions

We don’t just build coil winders; we create complete automation solutions. Our product portfolio includes:

- Automated Multi-Spindle Winders

- Terminal Insertion Units

- Soldering Stations

- Taping Mechanisms

- In-line Testing and Quality Verification Systems

This integrated approach ensures consistent product quality and optimal production efficiency.

Customer-Centric Customization

Every customer challenge is unique. That’s why our process begins with collaboration. From initial concept to final machine delivery, we work alongside your team to:

- Understand your production goals

- Analyze technical requirements

- Design tailor-made equipment

- Deliver solutions that exceed expectations

Our success is defined by our customers’ success. We take pride in building machines that not only meet but exceed industry standards.

A Commitment to Innovation and Community

Our mission goes beyond machinery. We aim to:

- Provide innovative, collaborative, and cost-effective solutions

- Maintain a profitable and growth-oriented business

- Create meaningful employment in our local community

In doing so, we contribute to the legacy of excellence that defines Door County, while shaping the future of manufacturing automation.

The Future Starts with the Right Coil Winder

Choosing the right coil winder is not a one-size-fits-all decision. It requires a deep understanding of your operational needs, production goals, and quality standards. By considering factors such as volume, complexity, automation, precision, and integration, you can make an informed choice that drives long-term value.

At Itasca Automation Systems, we specialize in turning complex challenges into streamlined solutions. With our expertise, advanced design tools, and customer-first philosophy, we are your ideal partner in achieving precision and productivity in coil winding.

Ready to Transform Your Coil Winding Process?

Contact us today to explore how our custom-designed, precision automation machinery can elevate your operations.

Call us to speak with a member of our engineering team. Let’s build the future of coil winding – together.

Comments are closed